QUICK SUMMARY

Most hot water tanks are susceptible to corrosion.

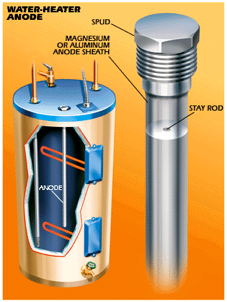

Magnesium (or aluminium) anodes are installed at time of manufacture to prevent the corrosion process attacking the tank. The anode will sacrifice itself to protect the tank. This ensures tank life is extended (potentially indefinitely) saving thousands of dollars of hot water system replacements due to rusted tanks.

All tank manufacturers recommend regular replacement of the anode. This is usually hidden away in the user manual and service notes. Most manufacturers would love you to continue to purchase a new tank every 5-10+ years.

|

|

The biggest problem with mixing steel and water together is the risk of corrosion to the steel tank itself. Even though the enamel coating is designed to slow this process down, water has an ability to always find a way. This is not unique to hot water tanks. The process of metal corrosion occurs all around us. Most of us are familiar with the Sydney harbour bridge that requires constant painting to ensure the steel structure is protected from the corrosive forces of water.

Your hot water tank is primarily suffering the same fate, but obviously you can keep painting the inside of your tank to prevent corrosion. Most property owners are not aware that their tank probably contains an ingenious way to prevent corrosion.